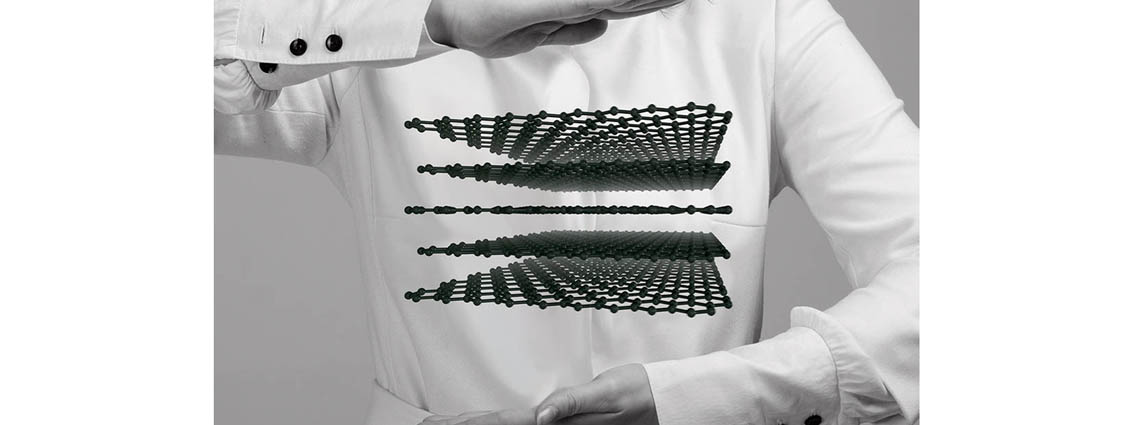

Graphene-based innovation

Graphene comes from the mineral graphite, which has been tried and tested for centuries and is well known, for example, for its use in pencils. It gives coatings and paints their innovative properties, such as durability, thermal conductivity, flexibility, longevity, range and homogeneity. This noticeably saves working time and reduces the effort of renovation work.

High-performance quality that convinces - The use of super-flat graphene nets with their outstanding properties in combination with the special paint formula make the ecological mineral paints Ecolith Interior and Ecolith Exterior a high-performance paint coatings.

The graphene-based innovation is the basis for the products' superiority. It gives the coatings and paints significantly better adhesion, resistance and elasticity. Large surfaces are formed in the colour matrix to ensure an enormously high range.

The topic of microplastics is playing an increasingly important role in environmental pollution. However, many pollutant influences are not immediately noticeable or recognisable. A Norwegian study* even found that about 17% of the microplastics produced worldwide are caused by the abrasion of paints and varnishes used outdoors, which are made up of plastic-containing binders such as pure acrylate, silicone resins or styrene acrylate. Thus, several tons of the hardly filterable plastic particles are released into the environment and partly into our organism every year. Despite its range of products and services and thanks to its consistently mineral character, Ecolith is completely free of microplastics or other environmentally harmful ingredients.

* „Sources of microplastics-pollution to the marine environment", Norwegian Environment Agency (Miljodirektoaret), 2014

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The following interview was conducted by the editors of FARBE UND LACK in April 2020

1. You have recently started using graphene in your paints. Which properties of the products are improved by this?

The use of graphene in lime paints makes it possible to offer this product class in unprecedented quality. The addition of mineral graphene with an immensely high surface area turns the otherwise brittle lime paint into a highly flexible paint. Thus, we can achieve the wet abrasion class 1 and even make it possible to use it as a facade paint, which is otherwise not possible with a lime paint.

2. Can you explain the principle of action? Why does graphene provide such improvements?

Graphene is based on graphite and forms very thin but extremely large surfaces that are very flexible. If these are homogeneously distributed in the lime paint, this large-area network stabilizes the lime and fillers in the paint by enclosing them. Furthermore, it is chemically virtually inert and able to have a water-repellent effect in the coating. The high flexibility and hydrophobicity give the new Ecolith products for interior and exterior use their special properties.

3. You promote your graphen-containing products with the fact that they are the result of years of research. What challenges did you have to overcome in developing the new technology?

The most difficult process in terms of production is due to the special features of the new products described above. For example, very large particles with a very high hydrophobicity are homogeneously dispersed in an aqueous medium, so that they cannot separate again in the finished product and the effect is thus permanent.

4. Auro is a natural paint manufacturer. Therefore we must of course ask about the origin of the graphene. How do you ensure that it comes from sustainable sources?

There are several manufacturing processes for the production of graphene, ranging from a pure laboratory process to production scale. Important for the manufacturing process is a constant product quality in order to have the above described dispersion process under control. To ensure sustainability, the graphene for AURO products is obtained from graphite. The manufacturing process is essentially a process based on pyrolysis.

5. You use graphene technology in mineral interior and exterior coatings. Why in such systems and do you plan to upgrade other coating systems with graphene?

The use of graphene raises the lime-based, mineral Ecolith products to a new, previously unattainable technical level. Since our customers are generally very strongly fixated on mineral coatings, it was only logical to make these products usable for outdoor use or for highly demanding indoor applications using graphene technology. At the moment we are also investigating how other products can be positively influenced by the use of graphene. We are currently thinking about testing effects on lacquers, stains and/or wall paints. The challenge here, however, is to be able to establish the graphene stably in the formulations. Compared to pure lime paints, these products are much more complex in their composition, which does not make the effort any easier.